- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

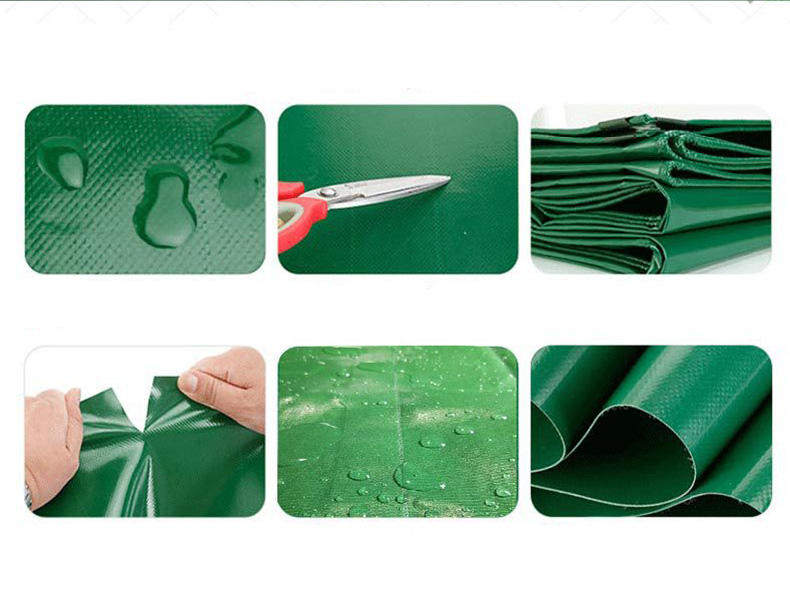

What is the process of PVC tarpaulin?

The main processing steps for PVC tarpaulin include:

1. Raw material preparation: Pre-treatment of the PVC tarpaulin substrate, such as cleaning and drying, to remove surface impurities and oil stains, improving the adhesion of the PVC powder.

2. Coating preparation: Mixing the PVC powder with appropriate additives to prepare a uniform coating slurry.

3. Fabric coating treatment: Heating the coated PVC tarpaulin substrate to a molten state to ensure a tight bond between the PVC coating and the substrate, improving adhesion and durability.

4.Heat sealing: Allowing the heat-sealed tarpaulin to cool naturally or by forced cooling to solidify and set the PVC coating.

5. Finished PVC Tarpaaulin inspection and packaging: Quality inspection of the finished PVC tarpaulin, checking whether the coating appearance, thickness, adhesion, and other indicators meet the requirements. Appropriately folding and packaging the qualified PVC tarpaulins to protect the quality and safety of the product during transportation and storage.